3D printing with PLA vs. PETG: What's the difference?

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read articleYou’ve come to the right place. Hubs is now Protolabs Network.

The same broad capabilities, exceptional quality and competitive pricing under a new brand.

EN

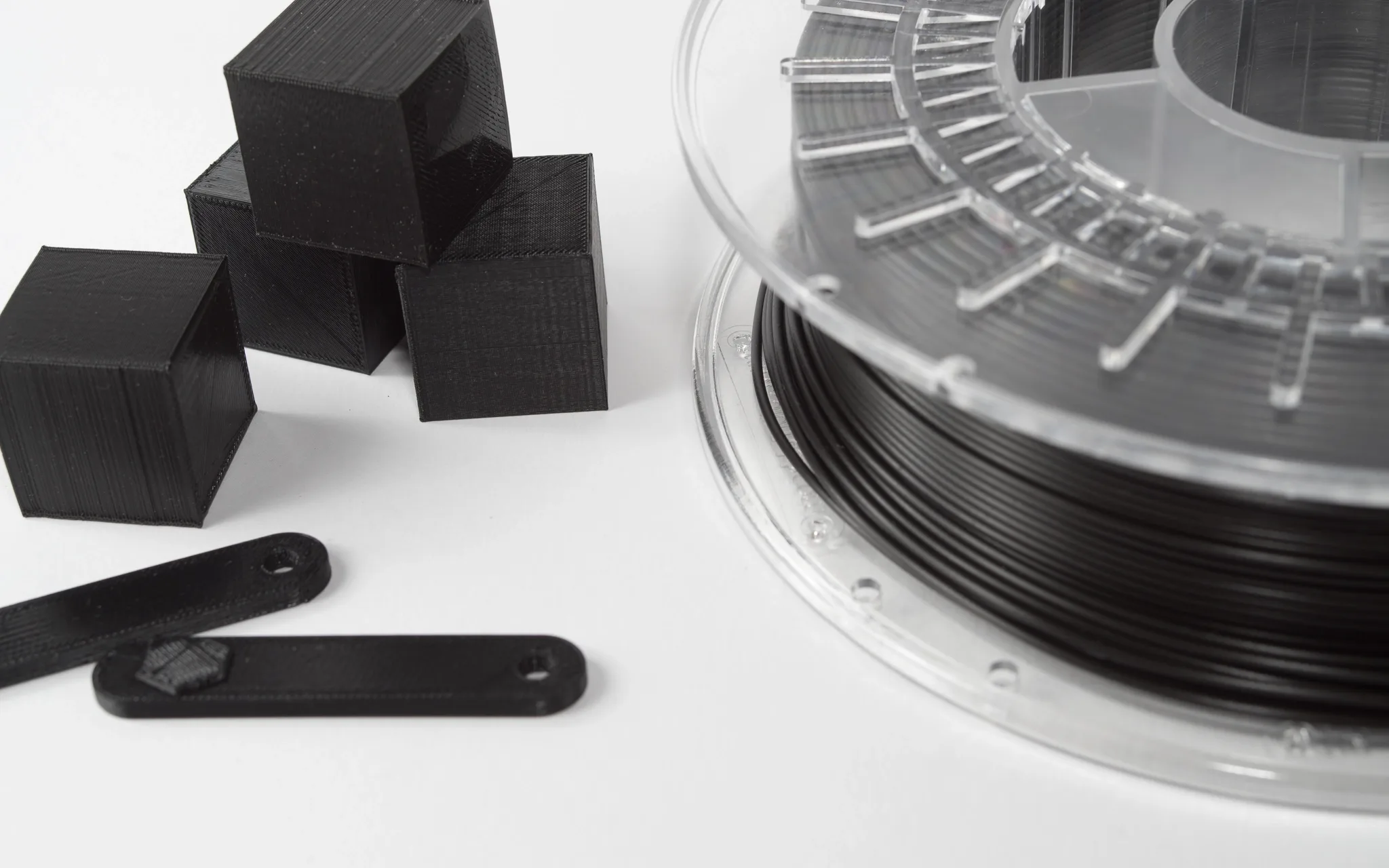

PLA and ABS are two essential materials for 3D printing with FDM. They are also two of the most popular materials on our platform. This comparison will help you choose which material to use for your 3D-printed custom parts.

PLA and ABS are the two most common materials for prototyping (desktop) FDM 3D printing (aside from, perhaps, PETG). As thermoplastics, both filaments enter a soft and moldable state when heated, returning to a solid-state when cooled. FDM printers melt and extrude PLA and ABS filament through a nozzle to build up parts layer by layer.

While both materials are used for FDM, they have key differences that make each more optimal for different applications. In this article, we’ll cover the main differences between these commonly used materials.

We also have this handy Youtube explainer video that covers the differences between PLA and ABS filaments.

Want to compare pricing for PLA and ABS?

PLA (Polylactic Acid) is a thermoplastic derived from renewable sources such as cornstarch or sugarcane. Biodegradable under the right conditions, PLA is one of the most popular bioplastics and is perfect for a variety of applications ranging from plastic cups to medical implants.

Compared to many other 3D printing materials, PLA is quite cost-efficient, providing good value for money in exchange for high-quality components with relatively smooth surface finishes. PLA is easy to print with and has a higher stiffness than ABS and other materials like nylon, though it doesn't handle high temperatures or significant stress so well. While PLA is stronger than ABS and nylon, it’s not very heat or chemical-resistant.

ABS (Acrylonitrile Butadiene Styrene) is another common thermoplastic. It's a common fixture in 3D printing and quite popular in the world of injection molding. Real-world applications of ABS include toys (think LEGO bricks), housings for electronics, automotive parts, household appliances and much more.

Tough and resistant to impact to a certain point, ABS has superior mechanical properties to PLA while being lighter and more durable. However, the tradeoff is that it's harder to print with and often requires higher temperatures for effective printing. The material can deflect heat more effectively than PLA, but it's absolutely not known for total heat resistance. And for 3D printer operators, be aware that ABS can produce strong odors during the manufacturing process.

PLA and ABS differ in several ways, including their unique tensile strength, density and ideal applications. The table below compares the key material properties of PLA and ABS filaments.

| Properties* | ABS | PLA |

|---|---|---|

| Tensile Strength** | 27 MPa | 37 MPa |

| Elongation | 3.5 - 50% | 6% |

| Flexural Modulus | 2.1 - 7.6 GPa | 4 GPa |

| Density | 1.0 - 1.4 g/cm3 | 1.3 g/cm3 |

| Melting Point | 200 ℃ | 173 ℃ |

| Biodegradable | No | Yes, under the correct conditions |

| Glass Transition Temperature | 105 ℃ | 60 ℃ |

| Spool Price*** (1kg, 1.75mm, black) | $USD 21.99 | $USD 22.99 |

| Common Products | LEGO, electronic housings | Cups, plastic bags, cutlery |

In general, the tolerances and accuracy of FDM printed components depend on printer calibration and model complexity. However, you can use PLA and ABS to create dimensionally accurate parts with printing details of 0.8 mm and minimum features of 1.2 mm. For connecting or interlocking parts, we recommend a tolerance of 0.5 mm and a minimum wall thickness of 1-2 mm. This will ensure that your part has adequate strength across all wall elements.

Thanks to its lower printing temperature, PLA is easier to print with and less likely to warp (when properly cooled). You can use PLA to print sharper corners and finer features than with ABS.

Want to improve your 3D printing design skills?

PLA and ABS have similar tensile strengths, making them solid options for many prototyping applications. Designers and engineers often prefer ABS due to its improved ductility over PLA. ABS has higher flexural strength and better elongation before breaking than PLA, which means that ABS can also be used for end-use applications. PLA, on the other hand, is more popular for rapid prototyping when the form is more critical than the function.

Overall, PLA is a good option for your custom parts if you don’t plan on putting them under a lot of physical stress (or UV radiation and high temperatures). ABS is more fitting for industrial applications and can weather physical strain better than PLA.

Both PLA and ABS print at nearly identical speeds. This means that you don’t have to change speed settings on your FDM machines when switching between materials. For PLA, printing at 60 mm/s is pretty standard, though some operators have printed at over 150 mm/s, so the standard speed is by no means a limit. You can also print ABS at the same speed, but between 40-60 mm/s is a bit more accurate for this material.

Whether you produce parts using PLA or ABS, FDM-printed components will always have visible layers. Using PLA often results in a glossier finish, while ABS typically prints in a matte finish. To smooth an ABS-printed part and give it a glossy finish, you can use acetone in post-processing. Sanding and additional machining are viable post-processing options for parts printed in ABS. You can also sand and machine PLA, though greater care is required.

If aesthetic quality is critical, then we recommend using SLA 3D printing to produce your custom parts.

Want to explore all the options for FDM post-processing?

For applications requiring higher temperatures, ABS (glass transition temperature of 105°C) is preferable over PLA (glass transition temperature of 60°C). PLA can rapidly lose its structural integrity and can begin to droop and deform as it approaches 60°C, especially if it's supporting a heavier load.

PLA is stable in general atmospheric conditions, though it will biodegrade within 50 days in industrial composters and 48 months in water. While ABS is not biodegradable, you can recycle it. This being the case, manufacturers tend to use PLA to produce items related to food service, though we absolutely recommend you get safety confirmation from filament manufacturers.

PLA is ideal when you’re looking for higher-quality aesthetics. Its lower printing temperature makes it easier to print with than ABS, especially if your parts have fine details.

ABS is best suited for applications where you need strength, ductility, machinability and thermal stability. Being more durable than PLA makes ABS a viable option for prototyping, low-stress end-use components and other practical applications. However, be aware that ABS is more prone to warping.

PLA and ABS are similar in terms of their tensile strengths, though engineers often go for ABS as it has better ductility than PLA. ABS has higher flexural strength and better elongation before breaking than PLA.

Unlike TPU, PLA and ABS aren’t flexible filament materials, though ABS is less brittle than PLA in nearly all applications.

PLA and ABS tend to have similar prices, which can reach approximately $40 to $75 (€36 to €68) per kg filament spool. ABS is likely cheaper than PLA if you’re considering only the cost of the raw materials. Also, PLA’s wider variety of brands, colors, and blends make it more popular than ABS.

Parts made from PLA and ABS will last a long time (decades, in fact), so long as they’re not used in a heavy load-bearing capacity.

When you heat any thermoplastic, it releases fumes, some of which may contain harmful particulates. PLA is plant-based, so it shouldn’t give off any bad odors or noxious fumes. However, ABS tends to be more toxic than PLA and can smell much worse. That’s why we recommend using a proper enclosure and ventilation system.

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read article

Learn the benefits of PLA and PLA+, when you should use one instead of the other, post-processing techniques that work for both materials, and more

Read article

Nylon, also known as polyamide (PA) is a synthetic polymer with high tensile strength, excellent resistance to wear and abrasion, and a low coefficient of friction. Here’s how it’s used in manufacturing and engineering applications.

Read article

Learn about the advantages and disadvantages of various methods of industrial 3D printing, materials that are commonly used, and more

Read article

Want to learn more about chemically resistant parts? Find out about common chemical-resistant materials, their advantages, disadvantages, and industrial applications.

Read article

Polylactic acid, also known as PLA, is a thermoplastic material commonly used in additive manufacturing. It is one of the most commonly used materials in 3D printing, and can be used to create a wide range of parts, packaging, and prototypes for the medical, food, cosmetics, and textile industries, among others.

Read article

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

Read article

What’s the best material for machining your parts? Check out this side-by-side comparison of the strength, price and application for CNC plastics and metals (in a handy, printable poster).

Read article

Multi Jet Fusion (MJF) is a 3D printing process for building prototyping and end-use parts fast. This article explains how MJF works and its main advantages.

Read article

Rapid prototyping uses 3D computer-aided design (CAD) and manufacturing processes to quickly develop 3D parts or assemblies for research and development and/or product testing.

Read article

This comprehensive guide compares the 25 most common materials used in CNC machining and helps you choose the right one for your application.

Read article

What are the different materials available for SLA 3D printing? This article compares the main printing resins, including standard, tough, durable, heat resistant, rubber-like, dental and castable, by material properties. Find the best material option for your application.

Read article

Learn the benefits of PLA and PETG, when you should use one instead of the other, post-processing techniques that work for both materials, and more.

Read article

Learn the benefits of PLA and PLA+, when you should use one instead of the other, post-processing techniques that work for both materials, and more

Read article

Nylon, also known as polyamide (PA) is a synthetic polymer with high tensile strength, excellent resistance to wear and abrasion, and a low coefficient of friction. Here’s how it’s used in manufacturing and engineering applications.

Read article

Learn about the advantages and disadvantages of various methods of industrial 3D printing, materials that are commonly used, and more

Read article

Want to learn more about chemically resistant parts? Find out about common chemical-resistant materials, their advantages, disadvantages, and industrial applications.

Read article

Polylactic acid, also known as PLA, is a thermoplastic material commonly used in additive manufacturing. It is one of the most commonly used materials in 3D printing, and can be used to create a wide range of parts, packaging, and prototypes for the medical, food, cosmetics, and textile industries, among others.

Read article

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

Read article

What’s the best material for machining your parts? Check out this side-by-side comparison of the strength, price and application for CNC plastics and metals (in a handy, printable poster).

Read article

Multi Jet Fusion (MJF) is a 3D printing process for building prototyping and end-use parts fast. This article explains how MJF works and its main advantages.

Read article

Rapid prototyping uses 3D computer-aided design (CAD) and manufacturing processes to quickly develop 3D parts or assemblies for research and development and/or product testing.

Read article

This comprehensive guide compares the 25 most common materials used in CNC machining and helps you choose the right one for your application.

Read article

What are the different materials available for SLA 3D printing? This article compares the main printing resins, including standard, tough, durable, heat resistant, rubber-like, dental and castable, by material properties. Find the best material option for your application.

Read articleShow more

Show less