Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. When needed to perfectly produce carbon fiber parts, Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Medical device technology is a field at the center of innovation. With the constant availability of new materials and designs, medical device manufacturers are always finding ways to make products that are durable, easy-to-use, and improve the end user’s lifestyle.

Fillauer, which was founded in 1914, is one of the industry leaders in the evolution, design, and technology of prosthetic and orthotic products. Its subsidiary, Fillauer Composites, is an organization that specifically designs carbon-fiber-based prosthetic feet. This means working with sensitive materials and tricky manufacturing processes to create world-class products.

| The Breakdown | |

|---|---|

| Organization | Fillauer Composites |

| Location | Salt Lake City, USA |

| Product | Prosthetic feet |

| Industry | Medical |

| Why Protolabs Network? | Short lead time, competitive pricing, reduced stress on manufacturing department. |

| Technology | Autoclave cure, water jet cutting, injection molding, FDM 3D Printing |

| Materials | Carbon fiber, ABS, Ninjaflex |

Fillauer Composites works with amputees, practitioners, and prosthetists to help test new products and to get design feedback. “It’s an incredibly subjective thing; you’re taking someone’s non-technical understanding of how it’s working and trying to translate that into actionable data and design features,” says Phil Thompson, design and manufacturing engineer at Fillauer Composites.

To properly utilize feedback and to make components, engineers at Fillauer Composites need to be able to quickly get prototype parts and produce non-carbon fiber components in a way that is both cost-effective and doesn’t burden the organization’s manufacturing department.

Material and Manufacturing Magic

Fillauer Composites works with a small selection of materials. The prosthetic feet they produce are primarily carbon fiber or fiberglass, with metal hardware components, such as aluminum or titanium. These materials help produce the clean, flawless, and sleek look that amputees want from a prosthetic.

Carbon fiber brings a lot of benefits: It is incredibly strong but fairly light, has high heat and pressure tolerances, and can easily fit complex design needs for non-traditional shapes.

Even with all its positives, engineers are still learning how to work with the material and manufacture it correctly. This takes a lot of time, and is Fillauer Composites’ main manufacturing focus, since it requires a lot of expensive machinery to properly produce prosthetic components.

“[Manufacturing with carbon fiber] is an incompletely understood art,” Thompson explains. “You feel like you have your process really well defined, and followed closely, and you’re using the same cure recipe and the autoclave and the same tools and materials during your layup process, then all of the sudden one finished part out of 10 will have some visual flaw or the thickness measurement will be a little bit off. It can be very hard to track down the root cause. A lot of times it’s purely speculative.”

To remove potential manufacturing errors, engineers extensively prototype parts to double check prosthetic assemblies. For these prototypes, Thompson says that they use elastomeric materials, which requires additional tooling and manufacturing workflows that they cannot support in-house at a reasonable scale.

Thompson says the manufacturing is almost 100 percent in house -- they have all the tools to prep and layup the carbon fiber. They cure everything with an autoclave and use a water jet to cut and section the material. This technology combination helps increase throughput and makes the overall process much cleaner.

“It is an incredibly specific process that requires manufacturing machinery with a pretty high upfront cost to make parts of a certain quality that [are] useful,” Thompson says.

They will use 3D printing for some parts because it’s just so much quicker to get a prototype instead of trying to work with in-house resources. Or, in certain cases, they don’t have the capabilities for some small, plastic widgets that are test components. “Sometimes it’s just not feasible for us to make it ourselves, even on a one-off basis, or to tie up our machine operation,” Thompson says.

A Transparent Manufacturing Conversation

Fillauer Composites uses Protolabs Network to get one-off and functional parts, especially as their engineers experiment with parts that are made from more elastomeric materials. “Even if they’re not functioning prototypes, we needed something to get an idea of the geometry and how it fits in with the foot assembly,” Thompson says. “That’s worked really well.”

“For production-level parts”, Thompson adds, “we work with Protolabs Network to manufacture a bracket that helps prosthetists attach the prosthetic foot to the amputee’s socket, which is fit onto the remaining limb. To make this bracket, we use ABS for the material and injection molding to produce the part”.

“Having Protolabs Network as our service partner makes it easier to cost-effectively produce our parts at scale. It also lets our manufacturing department specialize in perfecting the production of carbon-fiber parts, instead of spending time at setting up prototypes or manufacturing small, easily repeatable components”

For these plastic-based parts, working with Protolabs Network just took a lot of pressure off our manufacturing department. The 3D printing process really lends itself to making parts much more quickly and easily than a machining process,” Thompson says. “We’ve absolutely used Protolabs Network to prototype parts that would be impossible, or a nightmare, for us to machine in-house”.

📍 Download our free engineering guide for 3D printing here

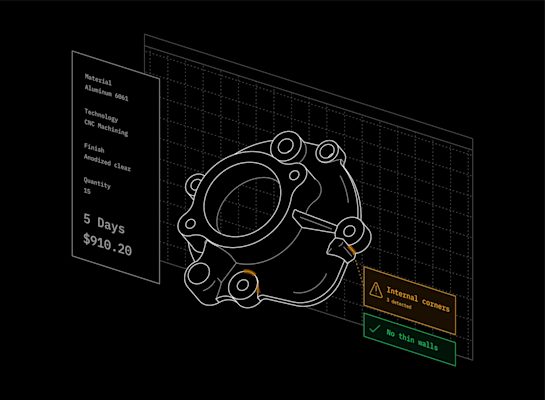

Thompson notes there’s been a learning curve with some of the finishes and finish quality, but Protolabs Network have made it easy to communicate what the part is being used for and what aspects are essential to include. Having this transparency and ongoing conversation throughout the whole design process removes any mystery from the production and ensures our engineers that they get the exact parts they need.

With a user-friendly web portal and open line of communication, Thompson can easily upload designs to Protolabs Network's support team and have them manage all production aspects, saving him a lot of time, being able to remove another task from his to-do list.

“I can describe to [Protolabs Network] what is going to be the most important feature about a print, as well as what the end use is, and they can tell me if they think that’s viable or not. Either way, we can work towards a functioning solution together … that’s been my favorite part about working with Protolabs Network,” says Thompson.

Upload your design today get an instant quote for your parts.