A guide to die casting

Die casting is a metal casting process in which a pressurized mold, or “die,” is used to produce complex metal parts, or “casts,” with high degrees of accuracy and consistency. Typically, die casting uses non-ferrous metals (those that do not contain iron), such as aluminum, zinc, magnesium, or copper. The process is used in a wide variety of industries to produce parts that are fit for production or end-consumer use. It is similar to injection molding, which essentially uses the same process, except with molten plastic rather than metal.

A brief history of die casting

The process of casting has been in existence for centuries, with its earliest known use dating back to the Han Dynasty in China, where bronze was used to create coins, mirrors, and other decorative items.

The die casting process specifically, however, gained popularity in the first half of the 1800s in Europe and North America, where it was used to produce parts for printing presses and other industrial machinery. The process was further refined in the early 20th century, when the use of aluminum and zinc alloys allowed for the production of lightweight, durable, and corrosion-resistant parts often used for industrial applications.

What is die casting used for now?

As the die casting process became more advanced and versatile, it began to be used in a wider range of industries. Today it is used in the following and many other industries:

-

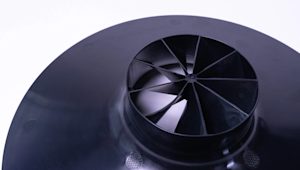

Automotive. Die casting is used to produce engine components, transmission parts, and body panels.

-

Aerospace. Die casting is used to produce components for aircraft engines, landing gear, and other critical systems.

-

Consumer electronics. Die casting is used to produce computer and mobile phone cases, camera bodies, and other high-end components.

-

Medical. Die casting is used to produce implants, surgical tools, and other medical devices.

How does die casting work?

Die-casting is typically a six-step process. Here we’ll take a look at each stage of the die casting process.

-

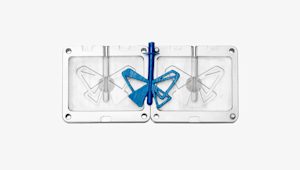

Mold design. The first step of the die casting process is designing the mold, which is made of non-ferrous metal. The mold is designed to the exact specifications of the desired part.

-

Mold preparation. The mold is prepared by applying a lubricant to prevent molten metal from sticking to it. The mold is then closed and clamped shut.

-

Injecting molten metal. Molten metal is injected into the mold at high pressure using a die casting machine. The pressure helps fill the mold completely and create a consistent part.

-

Part cooling. The mold is cooled using a cooling system, which helps molten metal to solidify and take the shape of the mold.

-

Part ejection. Once the part has solidified, the mold is opened, and the part is ejected from the mold using ejector pins.

-

Post-processing. The part is cleaned and finished, which may involve removing any excess material, polishing, applying a protective coating, or other post-processing techniques.

What are the advantages of die casting?

There are several advantages of using die casting to manufacture a part.

-

High production rate. Die casting can produce many parts in a short amount of time, making it an efficient process for mass or large-batch production.

-

Excellent surface finish. Molds used in die casting are made of high-quality materials, which can provide a high-quality surface finish to the parts they produce.

-

Dimensional accuracy. Die casting can produce parts with high dimensional accuracy and consistency, making it ideal for parts that require tight tolerances.

-

Design flexibility. Die casting can produce parts with complex shapes and thin walls, allowing for greater design flexibility.

-

Strength and durability. Die-cast parts are strong and durable, making them ideal for applications that require high strength and durability.

What are the disadvantages of die casting?

The following are disadvantages of using die casting to manufacture a part.

-

High tooling cost. The cost of making the molds used in die casting can be high, which makes it less economical for small production runs.

-

Limited material choice. Because die casting is primarily used for non-ferrous metals such as aluminum and magnesium, the number of materials that can be effectively used is limited.

-

Limited part size. Die casting is not suitable for producing large parts, as mold size is limited by the available press size.

-

Surface defects. Surface defects such as porosity, cracks, and warping can occur during the die casting process, which can affect the quality of final parts.

How do you design a mold for die casting?

When designing molds for use in die casting, it is important to consider factors such as wall thickness, draft angles, and the placement of gates and runners. You should also factor in the material being used and any specific requirements for strength, durability, or resistance. Here are a few tips for designing a mold for die casting.

-

Draft angles. A draft angle is necessary to enable a cast to be removed from the mold without damaging it. Typically, a draft angle of one to three degrees is recommended.

-

Wall thickness. The wall thickness of a die-cast part should be uniform and appropriate for the intended application. Thick sections may cause porosity and shrinkage, while thin sections may cause warpage or distortion.

-

Avoid sharp corners. Sharp corners can cause stress concentrations and cracking, so it is best to design parts with rounded edges.

-

Undercuts. Undercuts can cause difficulty in ejecting the casting from the mold, meaning they should be minimized or avoided.

-

Parting line. The parting line is the boundary where the two halves of the mold meet. It is important to design the parting line so that it does not interfere with any critical features of the part.

-

Gate design. The location and design of the gate, through which the molten metal is poured into the mold, can affect the quality of the cast. The gate should be located in such a way that allows for even filling and minimal turbulence.

-

Ejector pin placement. Ejector pins are used to remove a cast from a mold. Careful placement will allow you to avoid damaging a final part.

-

Surface finish. The surface finish of the cast is affected by the mold’s surface finish. A smooth surface finish can help minimize surface defects and improve a part’s appearance.

Want to get started with die casting or learn more about the process? Talk to our team at networksales@protolabs.com for technical advice, pricing and lead times.