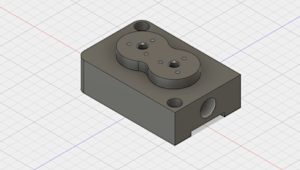

CNC machining is the most common subtractive manufacturing technology today and a hugely flexible and robust way to produce custom metal and plastic parts. Using CAD models, CNC machines precisely remove material from a solid block with a variety of cutting tools.

Overall, CNC machining produces parts with tight tolerances and impressive material properties. It’s suitable for single jobs and low-to-medium volume production (up to 1,000 parts), due to its high repeatability. However, it does come with more design restrictions than 3D printing, thanks in part to the subtractive nature of the technology.

In this introductory guide, we give you an overview of the basic principles of the technology and how these relate to key benefits and limitations. We also explain the key differences between the two main CNC machine setups: milling and turning.

Did you know we offer local sourcing for CNC machining?

How does CNC machining work? Let's talk milling and turning

The two main types of CNC (computer numerical control) machining systems are milling and turning. Due to the characteristics of each machine type, milling and turning are each uniquely ideal for manufacturing different geometries.

Let’s break down how parts are manufactured using these two distinct machine setups.

How does CNC milling work?

CNC milling is the most popular CNC machine architecture. In fact, the term CNC milling is often synonymous with CNC machining. CNC milling machines use rotational cutting tools to remove material from a part mounted on the machine bed.

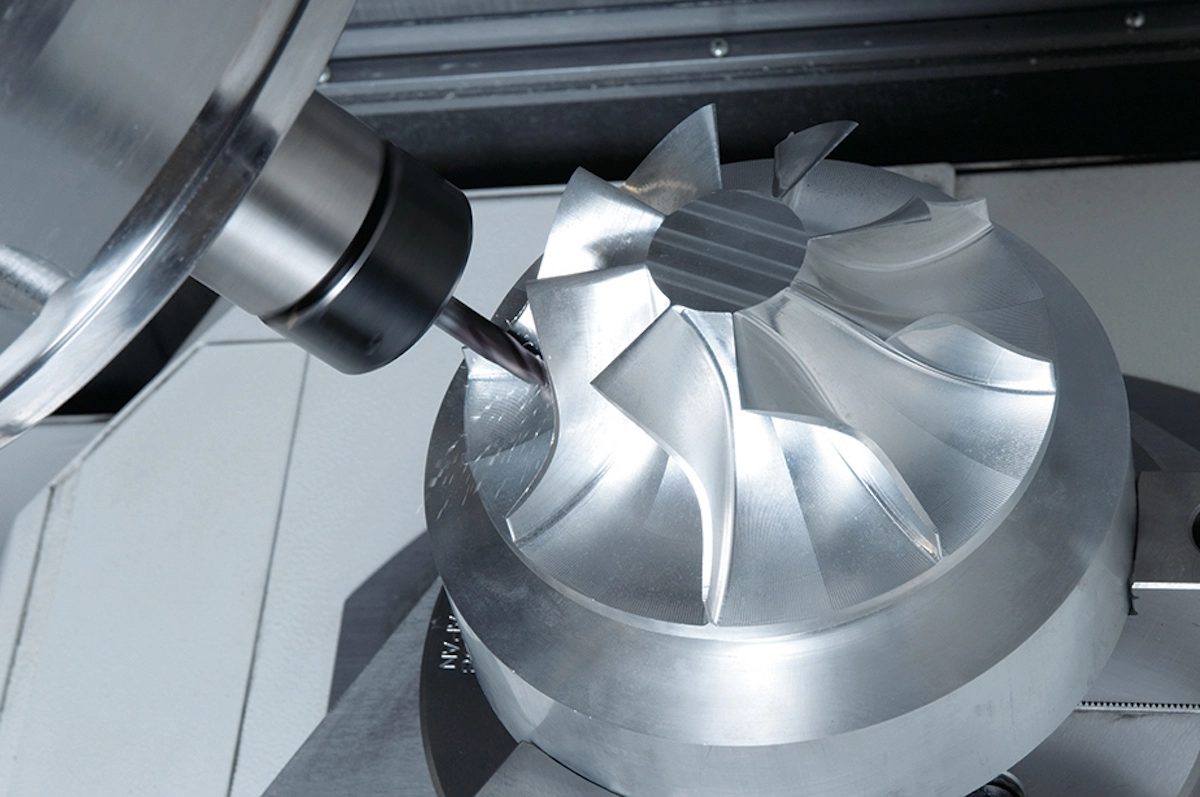

Most CNC milling systems have 3 linear degrees of freedom: the X, Y and Z axes. More advanced systems have 5 degrees of machining freedom via the rotation of the bed and/or the tool head (A and B axes). 5-axis machines can produce parts with high geometric complexity and may eliminate the need for multiple machine steps.

Here is an overview of how a CNC milling machine turns a CAD model into a custom part.

-

The operator converts a CAD model into a series of commands to be interpreted by the CNC machine (G-code).

-

A block of material—this is called the blank or the workpiece—is cut to size and placed on the build platform, using either a vice or a by directly mounting it on the bed.

-

It’s important to precisely position and align the workpiece to manufacture accurate parts. You can use special metrology tools (touch probes) to help with positioning and alignment.

-

Specialized cutting tools, rotating at very high speeds (thousands of RPM), remove material from the block. First, the machine removes material quickly at a lower accuracy to achieve an approximate geometry. Then, it takes a few higher accuracy passes to produce the final part.

-

If the model has features that can’t be reached by the cutting tool in a single setup, then the operator needs to flip the workpiece and repeat these steps.

After machining, you need to deburr a milled part. Deburring is the manual process of removing small defects from a finished part. These defects, generally found on sharp edges, come from material deformation during machining. For example, when a drill exits the far side of a through hole, it will leave blemishes that need removal.

Next, you want to inspect the part’s critical dimensions if tolerances were specified in the technical drawing. After you’ve completed this step, your part is ready for use or for post-processing. There is a lot to explore when it comes to post-processing for CNC-machined parts (milled and turned alike), so we recommend refreshing and/or leveling up your knowledge.

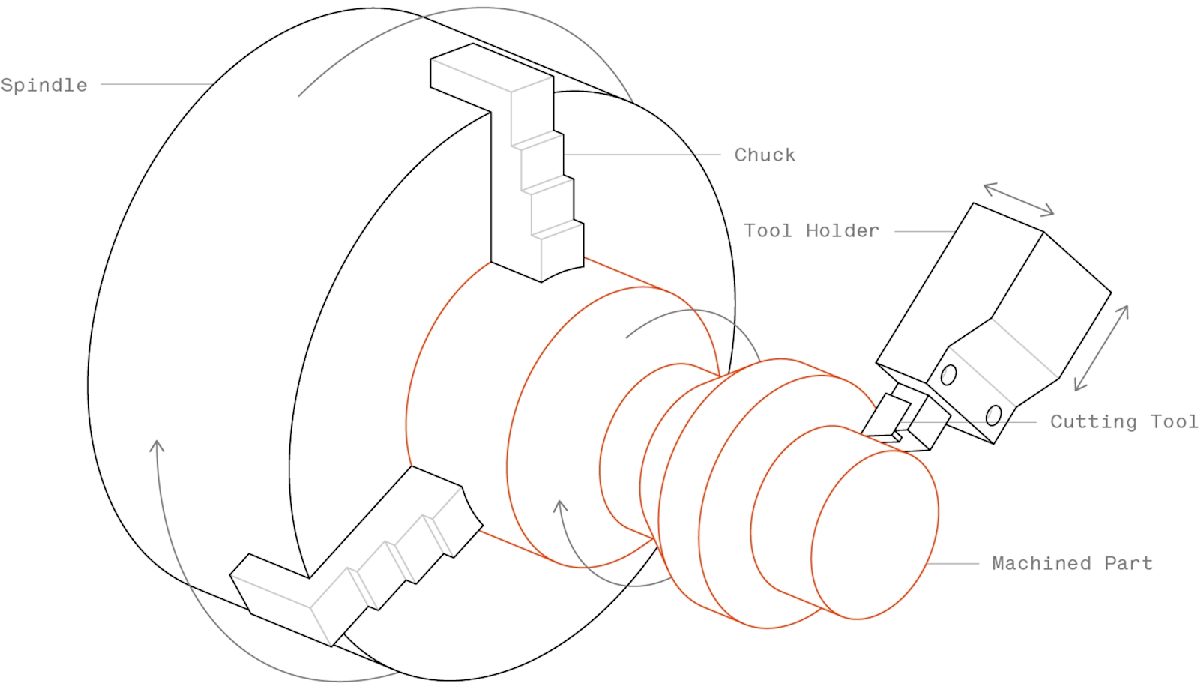

How does CNC turning work?

CNC turning machines use stationary cutting tools to remove material from a part, which is mounted on a rotating chuck. This is an ideal way to manufacture parts with symmetry along their center axis. Turned parts are typically produced faster and at a lower cost than milled parts.

Typically, CNC turning systems—also known as lathes—are used to create cylindrical parts. Modern multi-axis CNC turning centers, equipped with CNC milling tools, can manufacture non-cylindrical parts. These systems combine the high productivity of CNC turning with the capabilities of CNC milling and can manufacture a very large range of geometries with rotational symmetry, such as camshafts and radial compressor impellers.

Here is an overview of how a CNC turning machine manufactures parts.

-

The operator generates G-code from a CAD model and loads the machine with a cylinder of stock material (blank).

-

The part starts rotating at high speed and a stationary cutting tool traces a profile, progressively removing material until you have the designed geometry.

-

Internal cutting tools and center drills can be used to cut holes along the center axis of the workpiece.

-

If you need to flip or move the part, then you have to repeat this process. Otherwise, once you finish cutting away material, the part should be ready for use or further post-processing.

Since the line between CNC milling and turning systems tends to be blurred, the rest of this guide will focus mainly on CNC milling, as it's the more commonly used manufacturing process.

A quick guide to CNC machining parameters

Most machining parameters are determined by the machine operator when they generate G-code. The main parameters we’d like to cover are the build size and accuracy of CNC machines.

CNC machines have a relatively large build area, especially in comparison to 3D printers. CNC milling systems can machine parts with dimensions of up to 2,000 x 800 x 100 mm (78” x 32” x 40”), with CNC turning systems being able to machine parts with a diameter of up to Ø 500 mm (Ø 20’’).

You can manufacture parts with high accuracy and tight tolerances with CNC machining. CNC machines can even achieve tolerances of less than half the diameter of an average human hair (± 0.025 mm or .001’’).

If you don't specify the tolerance in the technical drawing, then an operator will typically machine the part with an accuracy of 0.125 mm (.005’’). The operator in this case fill follow is in the ISO2768.

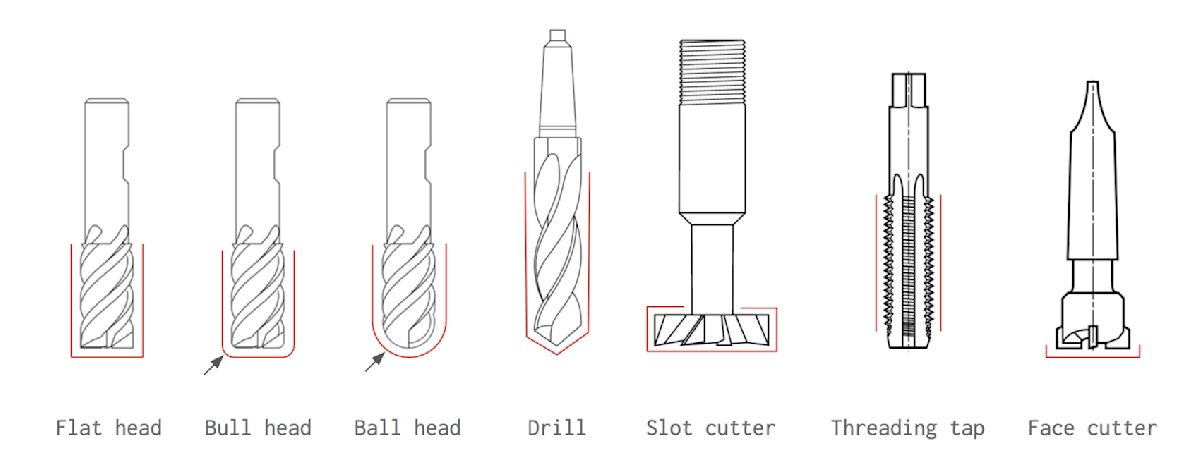

What are the most common cutting tools for CNC machining?

To create a wide range of geometries, CNC machines use many different cutting tools. Here are some of the most commonly used machining tools for milling.

The flat head, bull head and ball head tools are used to machine slots, grooves, cavities and other vertical walls. As they each have different geometric capabilities, they can machine many different types of features. Ball head tools are also commonly used in 5-axis CNC machining to manufacture surfaces with curvature and freeform geometries.

Drills are, of course, the most commonly used tool to create holes quickly and efficiently. You can find all of the standard drill sizes here. To create holes with non-standard diameters, you can use a plunging flat head tool (following a helical path).

The diameter of the shaft of slot cutters is smaller than the diameter of their cutting edge, which allows these milling tools to cut T-slots and other undercuts by removing material from the sides of a vertical wall.

Threading taps are used to manufacture threaded holes. To create a thread, precise control of the rotational and linear speed of the tap is required. Machine shops commonly still rely on manual tapping.

Face milling cutters are used to remove materials from large, flat surfaces. They have a larger diameter than end milling tools, so they require fewer passes to machine sizable areas. This reduces the total machining time for producing parts with flat surfaces. Operators will often take a face milling step during the machining cycle to prepare the dimensions of the block

You'll find an equally expansive range of cutting tools used in CNC turning, which cover all of your machining needs such as face cutting, threading and groove cutting.

CNC machining parts with geometric complexity: what are the design restrictions?

While CNC machining offers impressive design freedom, turning and milling machines can’t manufacture every geometry. Unlike with 3D printing, the more complex the design, the more it will cost to machine. This is due to the additional steps required for more complex parts.

The main restrictions associated with CNC machining have to do with the geometry of each individual cutting tool. The geometry of the tool determines a part’s radii, and most CNC cutting tools are cylindrically shaped and have a limited cutting length. These factors make sharp internal corners particularly challenging.

Access to tools is another major restriction with CNC machining. For instance, 3-axis systems can only achieve a certain level of part complexity. If you’re designing for a 3-axis machine, all part features will only be able to be accessed directly from above. 5-axis systems offer superior flexibility, as the angle between the part and the tool can be adjusted to gain access to more challenging to reach areas of the workpiece.

As well, parts with thin walls or other fine features are particularly difficult for CNC machines. Thin walls are prone to vibrations and may break due to the force of turning or milling. We recommend designing metal parts with a minimum wall thickness of 0.8 mm and plastic parts with a wall thickness of 1.5 mm.

Understanding how complex you can design your part for different types of machines, as well as what restrictions to keep in mind, is critical to ensuring your parts come out as designed and to the quality standard you’re looking for. For additional guidelines on how design can save you a lot of time and money on CNC machining, check out this article.

What are the characteristics of CNC machining?

A key strength of CNC machining is its capacity to consistently produce robust parts from a very wide selection of materials. CNC machines can handle pretty much every engineering material.

In contrast to 3D printing, parts manufactured via CNC machining have fully-isotropic physical properties that are identical to the properties of the bulk material from which they were machined.

CNC machining predominantly involves metals for both prototyping and larger production runs. It’s generally more difficult to machine plastics, as they have lower stiffness and melting temperatures, though one common use case we do see the merit in is CNC machining functional prototypes out of plastic before embarking on larger-scale production runs with injection molding.

How much do CNC machining materials cost?

There are a ton of materials available for CNC machining, which means the cost varies quite a bit between materials. Every material comes with a different price tag, and the physical properties of each material influences the overall cost of machining.

Aluminum 6061 is the most economical option if you’re opting to produce metal parts, with an approximate bulk cost of $25 for a blank with dimensions of 150 x 150 x 25 mm. ABS is the cheapest option, costing approximately $17 for a blank of the same size. And in terms of how ease of machining affects the cost, stainless steel is a good example. It’s much harder than aluminum and therefore more difficult to machine, increasing the total cost.

Here is a comprehensive overview of the most popular materials we offer on the Protolabs Network platform and their important characteristics.

| Material | Characteristics | Cost comparison |

|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, excellent machinability, low hardness | $ |

| Stainless Steel 304 | Excellent mechanical properties, resistant to corrosion & acid, relatively difficult to machine | $$$ |

| Brass C360 | High ductility, excellent machinability, good corrosion resistance | $$ |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents | $$ |

| Nylon (PA6 & PA66) | Excellent mechanical properties, high toughness, poor moisture resistance | $$ |

| POM (Delrin) | High stiffness, excellent thermal & electrical properties, relatively brittle | $$ |

How can I learn more about materials for CNC machining?

There is a lot to learn about all of the materials Protolabs Network offers for CNC machining. To take a deep dive into individual materials or sets of materials, check out these specialized videos, available on our Youtube channel.

Post-processing and surface finishes for CNC machining

CNC-machined parts that come right off the machine will generally have visible tool marks, which is not always desirable depending on your part requirements. There are many post-processing methods that can be used to improve the appearance of a part’s surface and boost its wear, corrosion and chemical resistance. Anodizing, bead blasting and powder coating are all viable methods for finishing your custom parts.

As this is a more general guide, we won’t go in-depth about post-processing and surface finishes. You can explore the most common techniques and finishes for CNC machining in this handy explainer.

What are the advantages and disadvantages of CNC machining?

While CNC machining is a viable and even ideal manufacturing process for many applications spanning prototyping to the medium-scale production of end-use parts, it’s not without its flaws. In this section, we cover the benefits and limitations of this subtractive machining process.

CNC machining offers excellent accuracy and repeatability. Both milling and turning can produce parts with very tight tolerances, which makes CNC ideal for high-end applications such as in the aerospace, aviation and automotive industries. Most materials used in CNC machining have excellent and fully-isotropic physical properties and are suitable for most engineering applications.

In general, CNC machining is the most cost-effective manufacturing process for producing low-to-medium numbers of metal parts. This means you can use CNC for single prototypes or to produce up to 1,000 units.

While these benefits make CNC machining an attractive option for engineers, the subtractive nature of the technology renders certain more complex geometries very costly or even impossible to manufacture.

Speaking from a financial perspective, the startup cost of CNC machining is much higher than it is for 3D printing. If you’re looking to produce low-cost prototypes from plastic, then 3D printing may be a better option where set-up is concerned.

Lead times for CNC machining tend to be longer than for 3D printing as well, as the average lead time for CNC is 10 days compared to the much lower 2-5 days for 3D printing. CNC machines are not as widely available as 3D printers, as they require more expert knowledge to operate effectively.

What are Protolabs Network's rules of thumb for CNC machining?

Let's break down the key parameters to consider for CNC machining both metal and plastic custom parts.

| Key CNC parameter | What Protolabs Network says |

|---|---|

| Dimensional accuracy | Typical: ± 0.125 mm (.005’’) Maximum: ± 0.02 mm (.0008’’) |

| Minimum wall thickness | Metals: 0.75 mm (0.030") Plastics: 1.5 mm (0.060") |

| Maximum build size | Milling: 2000 x 800 x 100 mm (78’’ x 32’’ x 40’’) Turning: Ø 500 mm (Ø 20’’) |

Ready to get your CNC parts into production?

Frequently asked questions

What's the best application of CNC machining?

CNC machining is ideal for one-off manufacturing jobs and for low-to-medium volume production of several hundred to 1000 parts. We recommend using CNC machining to produce your metal prototypes, as it’s the most price-competitive option. Also, you should opt for CNC machining when your parts need to have very tight tolerances.

What are the most common CNC machining cutting tools?

CNC machines use a variety of cutting tools to achieve a wider range of part geometries. These tools include drills, slot cutters, threading taps, face milling cutters and flat head, bull head and ball head tools.

Which industries use CNC machining the most?

CNC machining is a widely-used subtractive manufacturing process. A huge number of industries rely on CNC, including aerospace, automotive, aviation, transportation and other integral sectors. Airplane parts, for instance, have to be manufactured with an immense amount of precision to ensure the entire machine functions perfectly as designed.

Is CNC machining completely automated?

CNC machining is, for the most part, automated and reliant on pre-programmed software. CAD software sets the dimensions of a part, which CNC machines use to produce physical parts. In general, very little human intervention is required, though some complex processes may need an extra set of manual hands if the part design is uniquely complex. Overall, near-complete automation makes CNC machining a repeatable, trustworthy manufacturing process.

What's the general surface texture of CNC milled and turned parts?

As machined milled parts normally have a roughness of around 3.2μm (1.6μm depending on whether the machines are relatively new). When it comes to turned parts, we can reach a roughness of 0.8μm on the surface meaning that the speed of machining does not need to be adjusted.

How do you speed up CNC manufacturing?

Many factors affect the speed of manufacturing, including how your parts are designed and what surface roughness you'd like to achieve. Adding filets instead of sharp corners is a great example of how adjusting your design can help speed up the machining process. This is because the part can be produced with standard tools instead of changing them during machining.