Heat treatment involves the heating of metal alloys to (usually) extreme temperatures, followed by a cooling step under controlled conditions. The temperature the material is heated to, the time it is kept at that temperature and the cooling rate all greatly affect the final physical properties of the metal alloy.

Heat treatments can be applied to many metal alloys to drastically improve key physical properties, including hardness, strength and machinability. These changes happen due to modifications to the microstructure and, sometimes, the chemical composition of the material.

In this article, we review the heat treatments that are relevant to the most commonly used metal alloys in CNC machining to help you choose the right material for your applications.

What is heat treatment in CNC machining?

An integral step in CNC machining metal parts, heat treatment is the process of controlled heating and cooling of a material to achieve desired material properties. It alters four of the main material properties of metal parts, which are hardness, strength, toughness and ductility.

Of course, not all heat treatments are created equal. You choose the ideal heat treatment method based on the material composition, size of the part you’re producing and the required final material properties.

The goal of heat treatment is to achieve a particular microstructure that gives your parts certain material properties.

You can apply heat treatments to metal alloys at several stages of the CNC machining process, either before you start machining your parts or after.

Before CNC machining

When a standardized grade of a metal alloy is requested that is readily available, the CNC service provider will machine the parts directly from that stock material. This is often the best option for reducing lead times.

After CNC machining

Some heat treatments significantly increase the hardness of the material or are used as a finishing step after forming. In these cases, the heat treatment is applied after CNC machining, as high hardness reduces the machinability of a material. For example, this is standard practice when CNC machining tool steel parts.

What are common heat treatments for CNC materials?

Annealing, stress relieving & tempering

Annealing, tempering and stress relieving all involve the heating of the metal alloy to a high temperature and the subsequent cooling of the material at a slow rate, usually in air or in the oven. They differ in the temperature that the material is heated to and in the order in the manufacturing process.

In annealing, the metal is heated to a very high temperature and then slowly cooled to achieve the desired microstructure. Annealing is usually applied to all metal alloys after forming and prior to any further processing to soften them and improve their machinability. If another heat treatment is not specified, mo

st CNC machined parts will have the material properties of the annealed state.

Stress relieving involves the heating of the part to a high temperature (but lower than annealing) and is usually employed after CNC machining, to eliminate the residual stresses created from the manufacturing process. This way parts with more consistent mechanical properties are produced.

Tempering also heats the part at a temperature lower than annealing, and it's usually employed after quenching of mild steels (104

5 and A36) and alloy steels (4140 and 4240). This reduces their brittleness and improves their mechanical performance.

| Heat treatment |

Purpose |

Compatible materials |

| Annealing |

To improve the machinability of the metal alloy |

All metal alloys |

| Stress relieving |

To release residual stresses from mechanical deformation or temperature increase during processing |

All metal alloys |

| Tempering |

To reduce brittleness after quenching |

Mild steels (1045, A36) Alloy steels (4140, 4240) Tool steels (A2) |

Quenching

Quenching involves the heating of the metal to a very high temperature, followed by a rapid cooling step, usually by dipping the material in oil or water or exposing it to a stream of cool air. Rapid cooling "locks in" the changes in the microstructure that the material undergoes when heated up, resulting in parts with very high hardness.

Parts are usually quenched as a final step in the manufacturing process after CNC machining (think of blacksmiths dipping their blades in oil), as increased hardness makes the material more difficult to machine.

Tool steels are quenched after CNC machining to achieve their very high surface hardness properties. A tempering process may then be used to control the resulting hardness. For example, Tool steel A2 has a hardness of 63-65 Rockwell C after quenching but can be tempered to a hardness ranging between 42 to 62 HRC. Tempering prolongs the service life of the part, as it reduces brittle

ness (best results are achieved for hardness of 56-58 HRC).

| Heat treatment |

Purpose |

Compatible materials |

| Quenching |

To increase the hardness of the metal alloy |

Mild steels (1045, A36) Alloy steels (4140, 4240) Tool steels (D2, A2, O1) |

Precipitation hardening (aging)

Precipitation hardening or agin

g are two terms commonly used to describe the same process. Precipitation hardening is a three-step process: the material is first heated to a high temperature, then quenched and finally heated to a lower temperature for a long time (aged). This causes the alloy elements that initially appear as discrete particles of different compositions to dissolve and distribute uniformly in the metal matrix, in a similar way to how sugar crystals dissolve in water when the solution is heated.

After precipitation hardening, the strength and hardness of the metal alloys increase drastically. For example, 7075 is an aluminum alloy, commonly used in the aerospace industry, to manufacture parts of tensile strength comparable to stainless steel, while having less than 3 times the weight.

The effects of precipitation hardening in aluminum 7075 are illustrated in the next table:

|

Aluminum 7075-0(tempered) |

Aluminum 7075-T6(precipitation hardened) |

| Ultimate Tensile Strength |

280 MPa |

510–540 MPa |

| __Yield Strength __ |

140 MPa |

430–480 MPa |

| __Elongation at Break __ |

9-10% |

5–11% |

| Hardness (HV) |

68 |

175 |

Not all metals can be heat treated with this method, but the compatible materials are considered superalloys and are suitabl

e for very high-performance applications. The most common precipitation hardening alloys used in CNC are summarized below:

| Heat treatment |

Purpose |

Compatible materials |

| Precipitation hardening (aging) |

To increase the hardness & strength of the metal alloy |

Aluminum alloys (6061-T6, 6068-T6, 7075-T6) Stainless steel (17-4) |

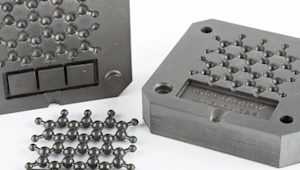

Case hardening & carburizing

Case hardening is a family of h

eat treatments that result in parts with high hardness, while the underline materials remain soft. This is often preferred over increasing the hardness of the part throughout its volume (for example, by quenching), as harder parts are also more brittle.

Carburizing is the most common case-hardening heat treatment. It involves the heating of mild steels in a carbon-rich environment and the subsequent quenching of the part to lock the carbon in the metal matrix. This increases the surface hardness of steels in a similar way that anodizing increases th

e surface hardness of CNC aluminum parts.

| Heat treatment |

Purpose |

Compatible materials |

| Case hardening & carburizing |

To increase the surface hardness of the metal part, while keeping the core soft |

Mild steels (1018, A36) |

How to specify a heat treatment on CNC orders with Protolabs Network

When you place a CNC machining order, there are three ways to request a heat treatment:

Give a reference to a manufacturing standard: Many heat treatments are standardized and widely used. For example, the T6 indicator in aluminum alloys (6061-T6, 7075-T6 and so on) shows that the material has been precipitation hardened.

Specify the required hardness

This is a common method of specifying a heat treatment for tool steels and case hardening. This will indicate to the manufacturer the heat treatment he needs to perform after CNC machining. For example, for D2 tool steel, it is common to request a hardness of 56-58 HRC.

Specify the heat treatment cycle

When the specifics of the required heat treatment are known, then these can be communicated to the supplier when placing the order. This way you can specifically modify the material properties for your application. Of course, this requires advanced metallurgical knowledge. We can help with all of these specifications.

Frequently asked questions

What are the different types of heat treatment?

There are four common methods for heat treatment, which include annealing, hardening, quenching and stress relieving.

What’s the purpose of heat treatment?

As heat treatment changes the microstructure of metals and alloys, it provides several benefits to the lifecycle of CNC-machined parts. Heat treatment is used to increase a part’s surface hardness, strength and ductility, and improve its temperature resistance.

What are the different types of annealing?

There are seven types of annealing, which include complete, isothermal, incomplete, spherification, diffusion (uniform), stress relieving and recrystallization annealing. Annealing often improves machinability, as well as the electrical and magnetic properties of a part.

What are the advantages and disadvantages of heat treatment?

Heat treatment provides many advantages for CNC-machined parts. This process helps manufacturers improve a part’s mechanical and chemical properties while reducing and preventing stress and distortion. Of course, heat treatment comes with its share of disadvantages, which include additional costs, surface oxidation and potential other contamination.

How do you specify heat treatment for CNC parts on the Protolabs Network platform?

You can specify a heat treatment in your CNC machining order as a “Custom requirement” by referencing a specific material temper, by providing a hardness requirement, or by describing a treatment cycle. Our mechanical engineers will review additional specifications you enter and may update the price.